Center for Computational Sciences and Simulation

CCSS research groups are supported in many ways by DFG Collaborative Research Centres (Transregional SFB 60, SFB 445, 491, 616), Priority Programmes (SPP 1239, 1386, 1486, 1538, 1599) and Research Units, as well as by BMBF Collaborative Projects and other funding.

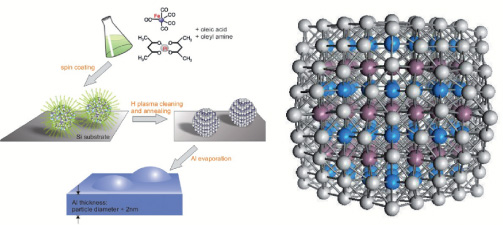

The research group of Professor Peter Entel uses the massively parallel computing platforms at the UDE or the Jülich Supercomputing Centre (JSC) in the investigation of contemporary problems in condensed matter physics, e. g. supporting the development of magnetic recording media in the nanometre range. Materials with technological potential in this area include iron-platinum nanoalloys. The hard magnetic properties of respective nanoclusters protected by a transition metal coverage as required for later applications were explored in collaboration with the experimental work groups of Professors Heiko Wende and Michael Farle.

Massively parallel computers are also used in the Faculty of Physics by Professor Peter Kratzer’s group for extremely complex electronic structure calculations of carbon defects in ZnO with the help of hybrid density functionals. This topic is to be pursued further in a joint project between the Kratzer and Entel groups.

The group of Professor Georg Jansen develops quantum chemical methods for the precise calculation of the strength of interactions between molecules and applies them to systems of experimental relevance. The focus lies on methods which extend the popular density functional theory approaches of chemistry and physics with an explicit determination of long-range electron correlation effects. In the medium to long term, these methods are intended to describe condensed molecular matter ab initio, i. e. in the ideal case without any help from experimental data. This is to be achieved through the use of model potentials derived from quantum chemistry in molecular dynamics simulations, which also represent an important instrument for the groups of Professor Spohr or Professor Hoffmann.

In Professor Eckhard Spohr’s group, ab initio molecular dynamics simulations of simplified models of water-filled pores in Nafion are performed. They have been able to show that, given a suitable chemical and physical structure of the pore (as characterized by the average distance between sulfonate groups), a sudden increase in proton mobility occurs above a certain water content. The threshold for this behaviour is similar to the experimentally observed onset of conductivity in Nafion membranes. Future methodological developments are intended to make it possible to model systems of increasing complexity on different time and length scales in an effort to understand the internal dynamics and chemical reactivity of nanostructured materials.

In the “Bioinformatics” research group of Professor Hoffmann, a new computational method for the diagnosis of HIV has been developed, together with other machine learning methods for the analysis of biological sequences. Further computational methods, such as molecular dynamics simulations, have been used to rationalize or predict biomolecular properties. In the future, biomolecules with novel properties will be developed for biomedical applications, and the evolution and diversity of viruses and micro-organisms will be characterized at the molecular level. The development of highly scalable numerical algorithms based on domain decomposition methods is one of the research topics of Professor Axel Klawonn and his group in Essen.

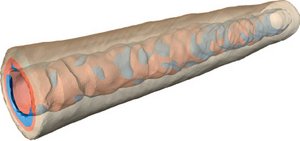

The development of numerical simulation methods and software for problems from structural and biomechanics has led to a software ecosystem that can successfully be used for parallel simulations of nonlinear, nearly incompressible elasticity problems originating from the field of atherosclerosis. These simulations have been successfully carried out on the Cray XT6m at the UDE. The simulations are part of a research collaboration between Professor Klawonn and Dr. Oliver Rheinbach with Professor Jörg Schröder of the Institute of Mechanics at the UDE in Essen and Professor Raimund Erbel and Dr. med. Dirk Böse from the West German Heart Center at Essen University Hospital.

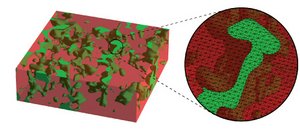

At the Institute of Mechanics, Professor Jörg Schröder and Dr. Daniel Balzani are working on a subproject of the DFG “Microplast” Research Group, with a focus on the finite element simulation of micro-heterogeneous steels using direct homogenization schemes. For this purpose, statistically representative volume elements (SSRVEs) are being constructed by solving an optimization problem based on statistical analysis of the microstructure. The extension of this method to three-dimensional SSRVEs requires real steel microstructures, which are analyzed in the group of Professor Dierk Raabe at the Max-Planck-Institut für Eisenforschung GmbH in Düsseldorf. The comparison of the simulations with experimental data is investigated in cooperation with Thyssen- Krupp Steel AG. Although the application of SSRVEs decreases complexity, efficient simulation demands the use of high-performance computers like the Cray XT6m.

“As accurate as necessary, as efficient as possible” can be seen as the construction principle behind the so-called Quasi-Continuum (QC) Method. In this atomistic-based finite-element method, full-atomic resolution and accuracy is invested only in highly loaded regions of metallic crystals. PD Dr. Bernhard Eidel at the Institute of Mechanics (Professor Jörg Schröder) also uses this adaptive method for the analysis of damage and failure mechanisms in structures and components on the length-scale up to some microns. In the future, simulations on even larger length scales are intended to open the door to relevant applications in microsystems technology.

The main focus of research at the Institute of Ship Technology, Ocean Engineering and Transport Systems (ISMT) is on the fields of computational hydrodynamics and fluid-structure interaction. For example, computational fluid dynamics is being used to predict the aero and hydrodynamic forces acting on ships navigating the river Elbe. The objective of this project is to calculate coefficients of the drag and lateral forces of selected ships for various angles of attack. The developed software will later form the basis for estimating tug power.

Questions in the field of statistical physics far away from the subject of equilibrium were the focus of the research activities of the group of Professor Dietrich Wolf. As part of SFB 616, they were able to clear up a controversial question regarding the velocity dependency of the friction force that decelerates a magnetic tip as it moves along a magnetic surface. The necessary massively parallel simulations of the classical spin dynamics of large systems were carried out in Jülich at the John-von-Neumann Institute for Computing (NIC) and on the local Cray at UDE.

Another research issue relates to sintering processes (SFB 445) and electromigration (SFB 616), i. e. the drift of surface atoms under the influence of gradients in the (electro) chemical potential. An extensive study on the influence of the crystalline misorientation of two nanoparticles on their coalescence was completed in this area. It is based on a newly developed hybrid algorithm that combines the kinetic Monte-Carlo simulation of atomic diffusion with the rigid-body dynamics of gravity and rotational degrees of freedom of particles. As part of SPP 1386, this research topic has been extended in collaboration with the experimental group of Dr. Gabi Schierning and Professor Roland Schmechel, with sample preparation for thermoelectric optimization of silicon nanopowder being performed by power-assisted compaction.

Kinetic Monte-Carlo simulations are also applied in the group of Professor Einar Kruis in the simulation of coagulation processes leading to nanoparticle formation. These computationally intensive simulations are performed with the help of low-cost GPUs (graphic processors), which allow massive parallel computations but also require new algorithms. The Monte Carlo and CFD methods are being combined in a follow-up project with other groups to monitor the product properties in nanoparticle synthesis. The Institute for Technology of Nanostructures (NST) is collaborating here with IUTA and the Institute for Combustion and Gasdynamics (IVG).

Professor Andreas Kempf ’s research group simulates turbulent reactive multi-phase flows by developing physical models which are implemented in computer programs and validated by comparison with experimental data. The group uses commercial software products, open source software and developments of their own which are particularly suited to applications on high performance computers. So far, massively parallel simulations with in excess of 100 million computational cells have already been performed with the PsiPhi program. The group’s ultimate aim is to optimize combustion processes.

The IVG also investigates mechanisms of high-temperature gas-phase reactions with close interaction between experiments, modelling and simulation in the groups of Professor Christof Schulz, Professor Andreas Kempf, Dr. Irenäus Wlokas, and Dr. Heidi Böhm. Applications of these mechanisms range from combustion processes to the synthesis of tailored nanomaterials in the gas phase. Research also investigates elementary steps in ignition and in-cylinder processes in combustion engines and supports the design of new synthesis facilities for nanomaterials.

Schematic representation (left) of the sample preparation (oxidized and ligand free) of the Al decorated Fe-Pt particles (right)

Visualization of a patient-specific arterial geometry

Finite element discretization of a three-dimensional steel microstructure in cooperation with Prof. D. Raabe of the Max-Planck Institut für Eisenforschung and Thyssen-Krupp Steel AG